An international manufacturer of abrasives for the automotive industry, our client required an efficient, reliable system capable of maintaining precise temperature and humidity conditions for consistent and quantifiable product testing, whilst ensuring a safe working environment.

Before worldwide distribution, each product batch had to be tested to exacting standards, and under exacting conditions. A 200m3 room and test chamber needed a supply of filtered air at a constant 20°C and 50% relative humidity, regardless of the outdoor ambient air being introduced. At the same time, potentially hazardous waste materials needed to be extracted from the test bed.

Our challenge was to design, build and supply a custom air conditioning system, and associated dust extraction system capable of meeting these demands, ensuring testing precision and the safety of all those involved.

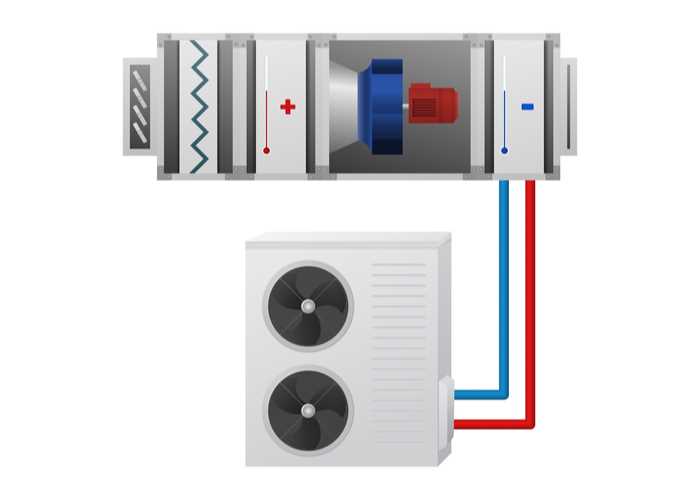

To ensure the required conditions were met and kept, we designed a custom Air Handling Unit (AHU) incorporating the following:

We also sourced an ATEX rated dust extraction system from Nederman that provided sufficient air flow and velocity at the vacuum head to cleanly and safely remove all waste material. Capability of the extraction system was of paramount importance, as the waste material in question can act as an explosive under certain conditions.

Installation and commissioning of this system needed to be carried out over a four week period, whilst still allowing the client to test the quality of current product batches.

The AHU was built up on site, manufactured to our specifications by ‘Daikin Applied’, and in sections small enough to enable access to the plant room.

Things didn’t always go to plan however. We discovered the Daikin condensing unit that served the cooling/dehumidification coil had inbuilt control limitations, but these were successfully overcome to create the exacting conditions the client required.

The system has now been running effectively for over two years and, as confirmed by the client’s data logging, is controlling the temperature and humidity exactly as specified. We continue to service this unit on a regular three monthly basis which ensures its reliability and performance.