The primary function of any chiller system is to remove excess or unwanted heat from the interior of a building. It’s a crucial aspect of Heating, Ventilation and Air Conditioning (HVAC) design in many settings, including:

Industrial - e.g factories and manufacturing plants

Medical - e.g hospitals and laboratories

Commercial - e.g shopping centres and hotels

Institutional - e.g schools and universities

When deciding on the best chiller system for a specific facility, several factors must be considered, such as total cooling requirement, the physical space available and any environmental concerns. Once these fundamentals have been identified, the choice of chiller typically comes down to one of two: a water cooled chiller or an air cooled chiller.

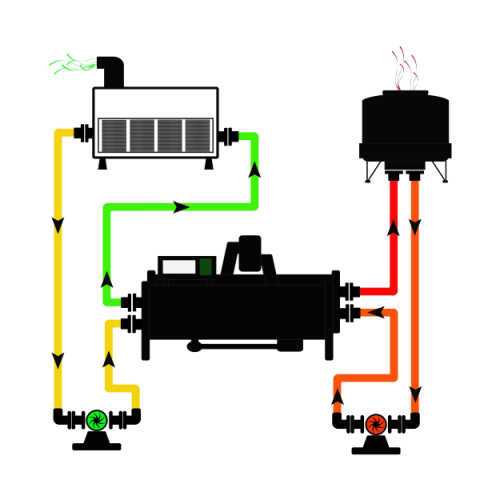

A water cooled chiller works by circulating chilled water through a closed loop system to absorb heat from a process or building.

The heat absorbed by the water is then transferred to the refrigerant in the chiller’s evaporator, which turns it into a gas. This gas is then compressed, raising its temperature and pressure, and directed to the chiller’s condenser. In the condenser, the hot gas is cooled and condensed back into a liquid by the flow of cool water through the condenser tubes. The cooled refrigerant is then pumped back to the evaporator to begin the cycle again.

In contrast, an air cooled chiller works by blowing air over the chiller’s condenser coils to transfer heat from the refrigerant to the surrounding air. The cooled refrigerant is then pumped back to the evaporator to absorb more heat from the process or building.

Essentially, the two systems serve the same purpose, but use a different medium to reject heat. So which is better for your specific application?

When choosing between a water cooled chiller and an air cooled chiller, it’s important to understand the advantages and disadvantages of each. A design engineer should discuss these pros and cons with you in detail, but broadly speaking they can be looked at in terms of cost, size and performance:

Installation cost: air cooled chillers are generally installed at a lower cost than water cooled chillers, mainly because there is no requirement for a cooling tower or the condenser water pumps that keep the system circulating.

Life cycle cost: while air cooled chillers have a lower upfront cost, water cooled chillers tend to operate at a lower cost over the long term. This is because air movement via fans requires more energy.

Maintenance costs: water cooled chillers require more frequent maintenance due to the continuous flow of water causing scale, mineral deposits and corrosion, especially on the cooling tower. In contrast, air cooled chillers require less maintenance but have a shorter lifespan and may require replacement sooner.

Installation size: smaller chiller systems are typically air cooled for cost reasons, while larger installations are mostly water cooled due to the lower long term operating costs and superior heat transfer properties.

Overall performance: water cooled chillers provide superior cooling on a square foot basis due to the heat transfer qualities of water compared to air.

In addition to the above pros and cons, there are other important factors that must be considered during the design phase. Some of these may sway a design engineer in favour of a certain type of system, or eliminate one completely.

Water availability: one important factor to take into account is the availability and cost of water in the local area. If water is scarce or expensive, it may not be practical or economically feasible to use a water cooled chiller, making an air cooled chiller the better option. Whilst this is not typically an issue in the UK, it still needs addressing in the evaluation stage.

Night time ambient temperature: an air cooled chiller may also be a better option in areas where the night time temperatures drop significantly lower than daytime temperatures. This is because an air cooled chiller can take advantage of the cooler conditions to reduce energy consumption and operating costs, and is particularly relevant for applications that require 24 hour operation.

Available space: air cooled chillers also have an advantage when space is limited or at a premium, since there is no requirement for a water cooling tower or mechanical room. However, they require significantly more space than water cooled chillers to achieve the same capacity, and there are portable water cooled chiller systems available for facilities with space constraints.

Airflow obstruction: obstruction to continuous airflow will have a severely negative impact on the performance of air cooled chiller units - high walls and other buildings or structures close by could all be an impediment to the airflow required for an air cooled chiller to work properly.

Noise of operation: due to the frequently running motors and fans, air cooled chiller systems are noisier in operation than water chiller units. This can cause issues, especially in densely populated residential areas.

When evaluating whether to choose a water cooled or air cooled chiller system, there are several important factors to consider. These include the overall system costs, the size of the HVAC unit, the ambient conditions at the installation location, the life cycle costs, and installation considerations.

Generally, water-cooled chillers are more efficient and have a longer lifespan than air-cooled chillers. However, they require more maintenance, and they also require a dedicated space for the cooling tower. Air-cooled chillers, on the other hand, are simpler to install and maintain, but are less efficient and require more space to achieve the same capacity.

Additionally, there are drawbacks associated with both water and air cooled systems that should be taken into account. For example, water availability and night time ambient temperatures can impact the feasibility of using a water cooled chiller system, whereas space considerations and airflow obstructions can affect the suitability of air cooled chillers.

Ultimately, there is no definitive answer as to which type of system is best. Design engineers must carefully evaluate each situation and location to determine which system will be the best fit based on the specific factors involved.

Our experienced engineers are on hand to discuss your cooling requirements, and advise on the best possible options for your needs.