Modern buildings, be they domestic, commercial or industrial, are designed to be as airtight as possible. Building them in this way minimises unintentional air leakage, preventing warm air from escaping a property.

Whilst that’s great for lowering energy costs and carbon emissions, there’s a negative knock on effect - inadequate ventilation. Throwing open windows and doors is not an ideal solution, since it overrides the purpose of an airtight building, and in some commercial and industrial settings, is simply not an option.

MVHR stands for mechanical ventilation with heat recovery, and helps meet the ventilation needs of energy efficient buildings.

As the name suggests, MVHR systems are dual purpose. Their role in energy efficient buildings is to provide:

Mechanical ventilation - the extraction of stale indoor air that can contain pollutants, allergens, odours and humidity, and the introduction of fresh, filtered air from outdoors.

Heat recovery - the recovery of otherwise wasted heat from the indoor air extracted.

MVHR systems can recover up to 90% of this otherwise wasted energy, so when these two processes work together, you have a constant supply of clean air that requires less energy to bring up or down to the desired temperature.

The result is a healthier indoor environment, reduced utility bills, and a lower carbon footprint.

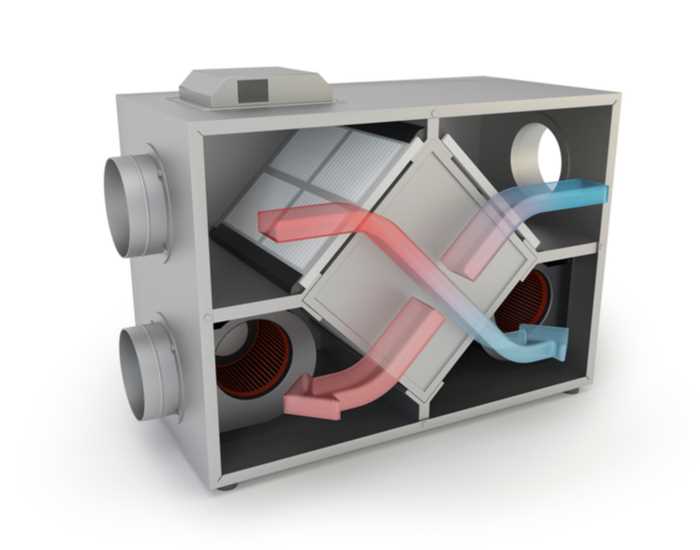

Without going into too much technical detail, MVHR systems work by way of ducting and a heat exchanger.

The cyclical process starts with the extraction of the stale indoor air. This is blown through ductwork directed outside of the building. On its journey, the air is routed to a heat exchanger - a highly efficient part of the system that absorbs and transfers heat energy.

Whilst the stale air is exhausted outside, fresh air is drawn in via another channel. This also passes by the heat exchanger, absorbing the bulk of the heat energy recovered from the outgoing or incoming air stream. This warmed/cooled air is then distributed throughout the premises, brought to the required temperature by way of additional heating or cooling systems.

The incoming air is filtered, and at no point does it come into contact with the outgoing air, so you can be sure it’s free from anything that may have a detrimental effect on your premises, its inhabitants, or operational activity.

With some systems, you’ll also find a ‘summer bypass’ functionality. This essentially shuts off the heat exchanger, so any unwanted heat energy is expelled outdoors in the warmer months.

Improved air quality - fresh air free from harmful particulates and bad odours, with balanced CO2 levels.

Lower energy costs and carbon emissions - essentially, you’re ‘recycling’ heat already generated and paid for.

Building preservation - with controlled humidity levels, you’ll protect the fabric of your building against things like mould and damp.

Controlled airflow - MVHR ensures fresh air is distributed in a controlled manner to each space, rather than random and restricted natural ventilation.

Less noise pollution - airtight buildings come with the advantage of minimum disruption from external noise, and with windows and doors shut, it’ll stay that way.

Improved productivity - whether in a business, school, or home office environment, fresh air boosts concentration, and helps minimise tiredness and lethargy.

The many benefits of MVHR make it an ideal solution in a variety of settings, provided the building in which it’s installed is sufficiently airtight, and the system designed for maximum performance.

At Loughborough Air Conditioning, we’ve installed MVHR systems in everything from radio stations to data centres, and are happy to offer practical guidance on your own ventilation needs.